Table of Contents

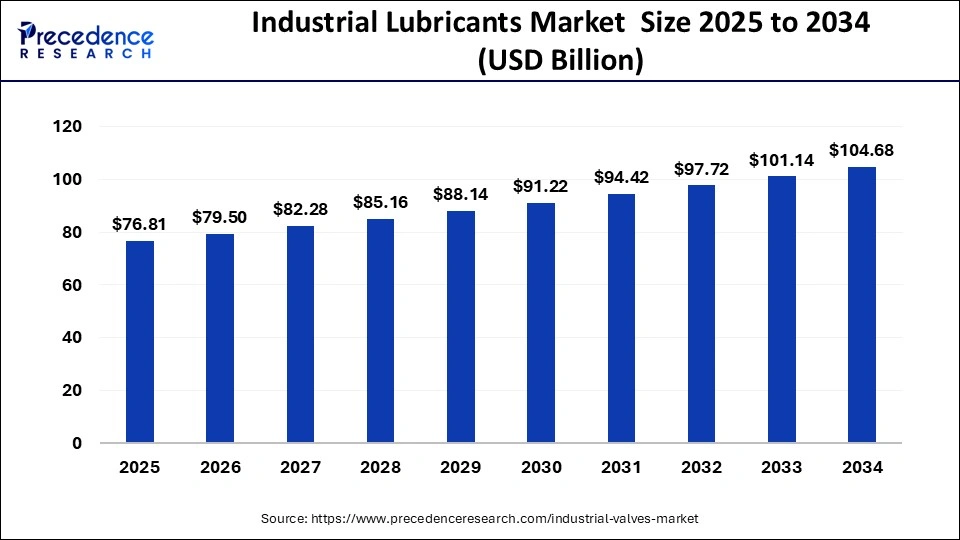

The global industrial lubricants market size accounted for USD 74.21 billion in 2024 and it is anticipated to reach around USD 104.68 billion by 2034 with a CAGR of 3.50%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1152

Introduction to Industrial Lubricants

Industrial lubricants are substances used to reduce friction between moving parts of machines and engines in various industrial applications. These lubricants are typically oils, greases, or fluids, made from base oils combined with additives to enhance their performance. The primary function of industrial lubricants is to reduce friction, wear, and heat generation between mechanical components, which can result in improved energy efficiency, better equipment performance, and reduced maintenance costs.

Industrial lubricants find applications in diverse industries such as automotive, manufacturing, energy, mining, construction, and more. With advancements in technology and growing industrial activities across the world, the demand for high-performance lubricants has significantly increased, making the market a critical segment within the global industrial supply chain.

Also Read: https://www.dailytechbulletin.com/metal-fiber-market-size/

Factors Driving the Growth of the Industrial Lubricants Market

Several factors are contributing to the growing demand for industrial lubricants. These include:

1. Rising Industrialization and Manufacturing Activities

Industrialization and manufacturing activities across emerging economies, particularly in Asia-Pacific and Latin America, are major contributors to the growing demand for industrial lubricants. Countries such as China, India, and Brazil are witnessing rapid industrial development, which requires advanced lubricants to support the increasing number of machines and equipment. The expansion of industries such as automotive, machinery manufacturing, and textiles is driving the need for effective lubrication solutions.

2. Technological Advancements in Lubricant Formulation

The development of high-performance lubricants that offer better efficiency, longer operational life, and reduced environmental impact is one of the key drivers of the industrial lubricants market. Advanced technologies in lubricant formulations, such as the use of synthetic oils, bio-based lubricants, and additives, are improving the performance of lubricants. These lubricants provide superior performance in extreme conditions such as high temperatures, heavy loads, and variable speeds, which are critical for industries like manufacturing, mining, and energy.

3. Demand for Energy Efficiency and Reduced Operational Costs

Energy efficiency is becoming a key focus for industries worldwide. Lubricants that reduce friction and energy loss, thereby improving overall machine efficiency, are in high demand. By reducing friction between components, industrial lubricants reduce the amount of energy required to operate machinery, leading to cost savings for businesses. Moreover, they help extend the lifespan of machines and reduce downtime, further contributing to operational efficiency.

4. Strict Regulatory Requirements and Environmental Concerns

The increasing concern for environmental sustainability and the growing stringency of environmental regulations are also driving innovation in the industrial lubricants market. Governments worldwide are imposing stricter regulations on the use of chemicals in lubricants, encouraging the development of bio-based, eco-friendly, and low-toxicity lubricants. Industrial lubricants that meet these regulatory standards are in demand, as companies seek to reduce their environmental footprint while ensuring compliance with local and international environmental laws.

5. Growth of the Automotive Industry

The automotive sector is a major consumer of industrial lubricants, and with the rising production of vehicles, particularly electric vehicles (EVs), there is a growing need for lubricants in the manufacturing process. Additionally, lubricants are essential for vehicle maintenance, including engine oils, transmission fluids, and grease for various mechanical components. The increasing demand for advanced engine oils and lubricants with high viscosity indexes and anti-wear properties is further boosting the market.

Key Applications of Industrial Lubricants

Industrial lubricants have a wide range of applications in various industries, helping in reducing friction, cooling, protecting against corrosion, and improving overall operational efficiency.

1. Automotive Industry

In the automotive industry, industrial lubricants are used in the manufacturing and maintenance of vehicles. Engine oils, transmission fluids, and grease are critical components that keep the automotive machinery functioning smoothly. With the growing adoption of electric vehicles (EVs), the demand for specialized lubricants such as low-viscosity oils and cooling fluids is increasing.

2. Manufacturing Industry

The manufacturing sector, which includes machinery, metalworking, and equipment manufacturing, is one of the largest consumers of industrial lubricants. These lubricants are used to ensure the smooth operation of machines such as CNC machines, turbines, compressors, and gears. Industrial lubricants also reduce the wear and tear of moving parts, preventing damage to expensive machinery and minimizing maintenance costs.

3. Mining and Construction

Mining and construction industries demand robust and durable lubricants that can withstand harsh operating conditions. Mining equipment such as excavators, trucks, and drills operate in extreme environments with high temperatures and heavy loads. Lubricants designed for these applications help reduce equipment wear, extend the operational life of machinery, and improve energy efficiency.

4. Energy Industry

In the energy industry, lubricants are crucial for turbines, pumps, and generators, where high levels of friction and temperature are common. Industrial lubricants help improve the efficiency of power generation and transmission equipment, reducing energy consumption and extending the equipment’s lifespan. As renewable energy sources like wind and solar power continue to grow, specialized lubricants for turbines and other related equipment are also seeing increased demand.

5. Aerospace

Aerospace industries require specialized lubricants that can withstand extreme temperatures and pressures. Lubricants used in aircraft engines, turbines, landing gears, and other components ensure smooth operation and prevent overheating. The growing air travel industry and the increasing use of advanced aerospace technologies are driving the demand for high-performance lubricants in this sector.

6. Food Processing Industry

The food processing industry requires lubricants that are non-toxic and food-safe. These lubricants are used to lubricate machinery involved in food manufacturing, packaging, and transport. They must meet stringent safety and hygiene standards and often need to be biodegradable to reduce their environmental impact.

Trends Shaping the Future of the Industrial Lubricants Market

Several trends are emerging that will influence the direction of the industrial lubricants market in the coming years. These include:

1. Increasing Adoption of Bio-based Lubricants

Bio-based lubricants, derived from renewable sources like vegetable oils, are gaining popularity due to their environmentally friendly properties. These lubricants offer the same performance as traditional mineral oils but are biodegradable, making them less harmful to the environment. As companies look for sustainable alternatives, bio-based lubricants are expected to become more widely adopted across industries such as agriculture, automotive, and manufacturing.

2. Development of Smart Lubricants

The rise of the Internet of Things (IoT) and Industry 4.0 is paving the way for smart lubricants. These lubricants contain sensors that monitor the condition of machinery and provide real-time data on lubricant performance. This innovation allows companies to predict maintenance needs, prevent unexpected downtime, and optimize lubricant usage, ultimately improving operational efficiency.

3. Synthetic Lubricants and High-Performance Solutions

The demand for synthetic lubricants, which offer better performance and longer service life, is increasing. Synthetic lubricants are engineered to withstand extreme operating conditions and offer superior protection against wear, oxidation, and corrosion. These lubricants are becoming the preferred choice in high-demand industries such as automotive, aerospace, and heavy machinery.

4. Digitalization and Automation in Lubricant Management

With the growth of industrial automation, digital technologies are increasingly being applied to lubricant management. Systems that monitor lubricant levels, optimize usage, and track performance are becoming more common. These technologies help companies reduce waste, improve efficiency, and manage lubrication costs more effectively.

Regional Insights

The global industrial lubricants market is influenced by regional factors such as industrial growth, technological advancements, and regulatory standards.

North America

North America, particularly the United States, is one of the largest markets for industrial lubricants. The strong automotive, manufacturing, and energy sectors in the region, combined with the increasing adoption of advanced lubrication technologies, are driving the demand for industrial lubricants.

Europe

Europe is another key region for industrial lubricants, with a focus on sustainability and innovation. The automotive and manufacturing industries in countries like Germany, France, and the United Kingdom are major consumers of industrial lubricants. The growing regulatory emphasis on eco-friendly lubricants is also shaping market dynamics in this region.

Asia-Pacific

Asia-Pacific is expected to witness the highest growth rate in the industrial lubricants market. The rapid industrialization of countries like China and India, coupled with the growing demand for lubricants in automotive, manufacturing, and energy sectors, is driving market expansion. Additionally, the region’s large population and increased industrial activity in countries like Japan and South Korea further contribute to the demand.

Latin America and the Middle East & Africa

In Latin America and the Middle East & Africa, growing industrial activities in countries like Brazil, Saudi Arabia, and South Africa are boosting the demand for industrial lubricants. The expanding oil and gas, automotive, and construction industries are expected to drive market growth in these regions.

Key Players in the Industrial Lubricants Market

Some of the leading players in the global industrial lubricants market include:

- Fuchs Group

- Exxonmobil Corp

- The Lubrizol Corporation

- Phillips 66

- Royal Dutch Shell

- Lucas Oil Products, Inc.

- Bel-Ray Co., Inc.

- Amsoil, Inc.

- Kluber Lubrication

- Chevron Corp.

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/