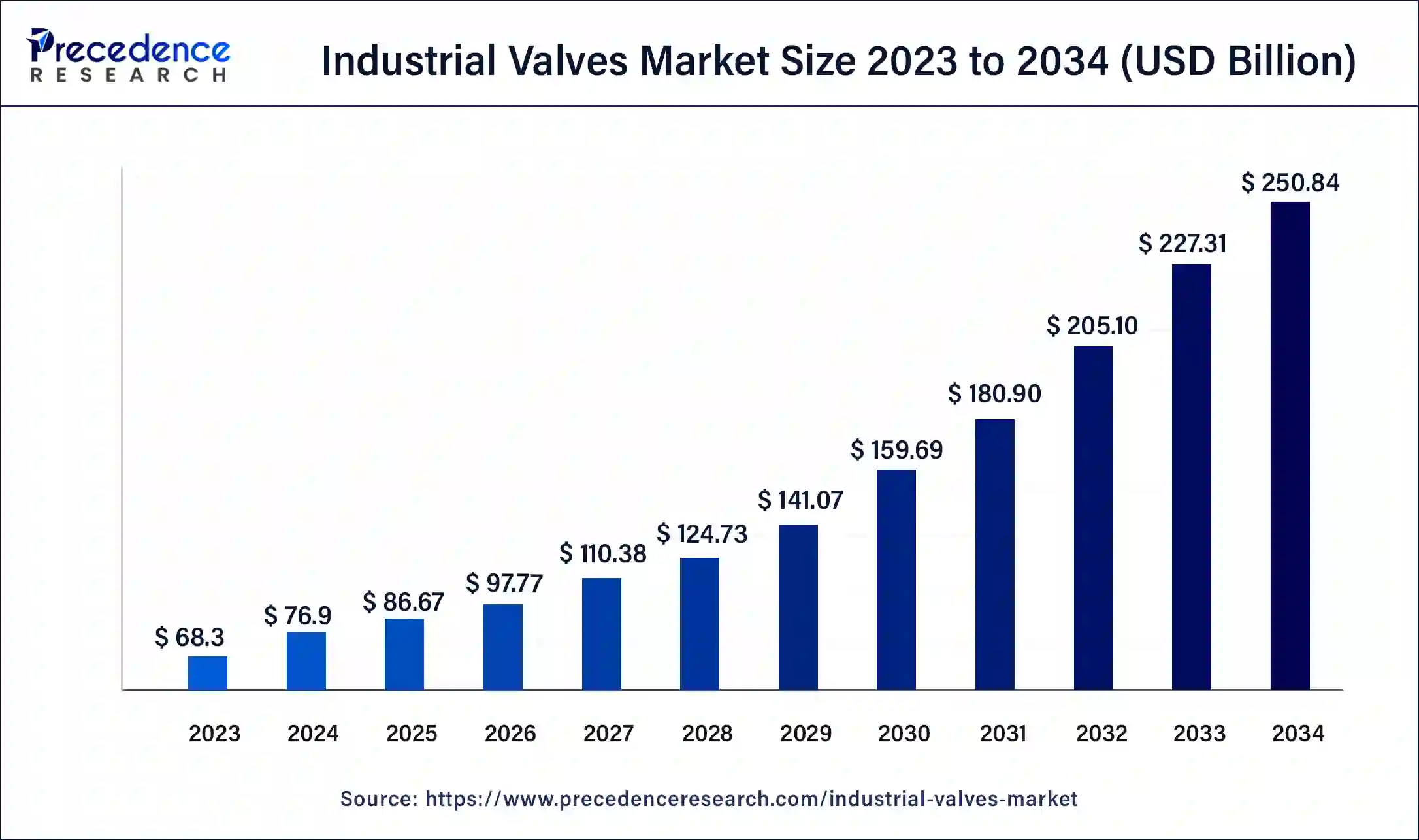

The global industrial valves market size accounted for USD 76.9 billion in 2023 and is projected to reach USD 250.84 billion by 2034, growing at a CAGR of 12.6%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1076

Key Insights

- In 2023, Asia Pacific dominated the market, capturing the largest market share of 36%.

- The steel industrial valves segment held the highest share by material type in 2023.

- The oil & gas sector accounted for the largest revenue share by application in 2023.

- The water & wastewater segment is projected to grow at a CAGR of 6% during the forecast period.

Market Dynamics

Drivers

The growing emphasis on energy efficiency and process automation is driving the demand for industrial valves across multiple industries. As industries strive to enhance productivity while reducing operational risks, the adoption of high-performance and smart valves is increasing. The surge in oil & gas exploration, coupled with infrastructure developments in emerging economies, is contributing to market expansion. Additionally, the demand for valves in power plants, water distribution networks, and chemical processing facilities continues to grow due to strict environmental and safety regulations.

Opportunities

The rapid urbanization and industrialization in developing countries present new growth opportunities for the industrial valves market. The increasing investments in smart cities and industrial automation projects require advanced valve technologies for seamless operations. Additionally, the expansion of the pharmaceutical and food processing industries is driving demand for sanitary and high-precision valves. The trend toward digitalization and predictive maintenance solutions also offers opportunities for innovation, as industries seek to improve asset performance and reduce downtime.

Challenges

One of the main challenges in the industrial valves market is ensuring product durability and performance under extreme conditions. Industrial valves often operate in harsh environments, including high-pressure and corrosive settings, leading to frequent wear and tear. The presence of counterfeit products in the market affects the reputation of established brands and poses safety risks. Additionally, the volatility in raw material prices and supply chain disruptions can impact production timelines and increase costs for manufacturers and end-users alike.