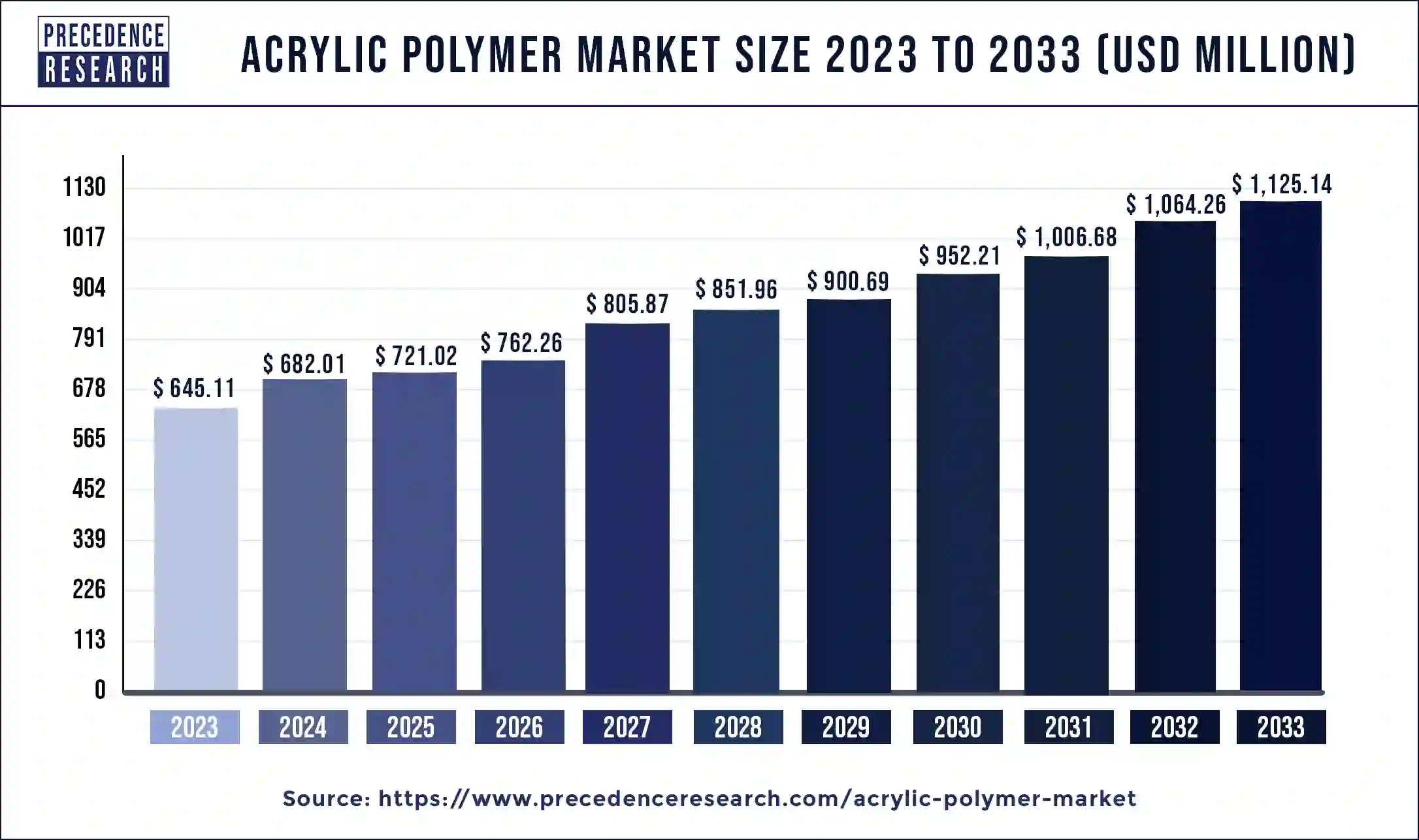

The global acrylic polymer market size was estimated at USD 645.11 million in 2023 and is projected to reach around USD 1,125.14 million by 2033, growing at a CAGR of 5.72% from 2024 to 2033.

Key Points

- North America dominated the market share in 2023.

- Asia-Pacific is estimated to expand at the fastest CAGR between 2024 and 2033.

- By type, the polymethyl methacrylate segment held the largest market share 22% in 2023.

- By type, the polyvinyl acetate segment is anticipated to grow at a remarkable CAGR between 2024 and 2033.

- By solution type, the water-borne segment generated the biggest market share 28% in 2023.

- By solution type, the solvent-borne segment is expected to expand at the fastest CAGR over the projected period.

- By application, the cosmetics segment has held a major market share of 31% in 2023.

- By application, the paints & coatings segment is expected to expand at the fastest CAGR over the projected period.

The acrylic polymer market is witnessing substantial growth worldwide, driven by diverse applications across industries such as construction, automotive, paints and coatings, adhesives, and textiles. Acrylic polymers, derived from acrylic acid or its derivatives, offer desirable properties such as high transparency, weather resistance, chemical stability, and durability, making them indispensable in various end-use sectors. The market is characterized by continuous product innovation, technological advancements, and increasing demand for sustainable and eco-friendly materials, driving expansion opportunities across global markets.

Get a Sample: https://www.precedenceresearch.com/sample/3978

Growth Factors:

Several factors contribute to the robust growth of the acrylic polymer market. One key driver is the increasing demand for acrylic-based products in the construction industry. Acrylic polymers are widely used in architectural coatings, sealants, adhesives, and waterproofing membranes due to their excellent adhesion, UV resistance, and weatherability. Rapid urbanization, infrastructure development projects, and growing investments in residential and commercial construction fuel the demand for acrylic polymers, especially in emerging economies.

Moreover, the automotive sector represents a significant growth opportunity for acrylic polymers, driven by the rising demand for lightweight materials, fuel efficiency, and enhanced aesthetics. Acrylic-based paints, coatings, and emulsions find extensive application in automotive exterior and interior components, offering superior color retention, gloss, and scratch resistance. Additionally, stringent regulations aimed at reducing VOC emissions and enhancing environmental sustainability promote the adoption of water-based acrylic coatings and finishes in the automotive industry.

Furthermore, the paints and coatings sector remains a major end-user of acrylic polymers, accounting for a significant share of market demand. Acrylic-based paints and coatings exhibit fast drying times, excellent color retention, and resistance to fading, making them ideal for architectural, industrial, and decorative applications. The growing preference for low-VOC and eco-friendly coatings, coupled with increasing investments in infrastructure and renovation projects, drives market growth for acrylic polymer-based coatings globally.

Region Insights:

The acrylic polymer market demonstrates a global presence, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. North America and Europe represent mature markets for acrylic polymers, characterized by established infrastructure, stringent regulatory standards, and a strong focus on innovation and sustainability. The presence of major acrylic polymer manufacturers, technological advancements, and robust demand from end-use industries contribute to market growth in these regions.

In Asia-Pacific, rapid industrialization, urbanization, and infrastructure development activities drive significant demand for acrylic polymers. Countries such as China, India, and Japan are key contributors to market growth, supported by expanding construction, automotive, and manufacturing sectors. Additionally, favorable government initiatives, foreign investments, and increasing consumer spending on home improvement and automotive aftermarket products fuel market expansion across the region.

Latin America and the Middle East and Africa regions offer lucrative growth opportunities for the acrylic polymer market, propelled by infrastructure development projects, construction activities, and expanding automotive production. Rising investments in residential and commercial construction, infrastructure modernization, and automotive manufacturing drive demand for acrylic-based paints, coatings, and adhesives in these regions. Moreover, increasing awareness of environmental regulations and sustainability initiatives further stimulate market growth for eco-friendly acrylic polymers.

Acrylic Polymer Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 5.72% |

| Global Market Size in 2023 | USD 645.11 Million |

| Global Market Size by 2033 | USD 1,125.14 Million |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Type, By Solution Type, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Acrylic Polymer Market Dynamics

Drivers:

Several drivers underpin the growth of the acrylic polymer market. One of the primary drivers is the versatility and performance advantages offered by acrylic polymers across diverse applications. Acrylic-based products provide superior weatherability, UV resistance, color retention, and durability compared to conventional materials, making them preferred choices in various industries. The ability of acrylic polymers to enhance product performance, aesthetics, and longevity drives their widespread adoption and market demand.

Additionally, technological advancements in acrylic polymer synthesis, processing, and formulation contribute to product innovation and performance optimization. Manufacturers continuously invest in research and development to develop novel acrylic polymers with improved properties, such as enhanced adhesion, scratch resistance, and chemical stability. Advanced manufacturing techniques, including emulsion polymerization, solution polymerization, and suspension polymerization, enable the production of tailor-made acrylic polymers for specific end-use applications, driving market competitiveness and differentiation.

Furthermore, increasing environmental awareness and regulatory initiatives to reduce VOC emissions and promote sustainable materials drive market demand for eco-friendly acrylic polymers. Water-based acrylic emulsions and solvent-free acrylic coatings offer environmentally responsible alternatives to solvent-based formulations, aligning with sustainability goals and consumer preferences. The adoption of acrylic polymers with low VOC content, recyclability, and biodegradability enhances market competitiveness and supports sustainable growth in the acrylic polymer market.

Opportunities:

The acrylic polymer market presents numerous opportunities for growth and innovation. One significant opportunity lies in expanding applications beyond traditional end-use sectors. Acrylic polymers find emerging applications in renewable energy, electronics, healthcare, and packaging industries, driven by their unique properties and performance advantages. Innovations in acrylic polymer chemistry, such as conductive acrylics for electronics, bio-based acrylics for medical devices, and barrier coatings for food packaging, unlock new market opportunities and revenue streams.

Moreover, the growing demand for sustainable and bio-based materials creates opportunities for manufacturers to develop acrylic polymers from renewable feedstocks and bio-derived monomers. Bio-based acrylic polymers offer environmental benefits such as reduced carbon footprint, lower dependency on fossil fuels, and enhanced biodegradability compared to conventional acrylics. Strategic partnerships, research collaborations, and investments in bio-based technologies enable companies to capitalize on the growing market demand for sustainable acrylic polymers and gain a competitive edge.

Furthermore, market expansion initiatives in emerging economies present opportunities for acrylic polymer manufacturers to tap into new geographic markets and customer segments. Rising urbanization, infrastructure development, and consumer spending in Asia-Pacific, Latin America, and Africa create demand for high-performance acrylic-based products in construction, automotive, and consumer goods sectors. By establishing local production facilities, distribution networks, and strategic alliances with regional partners, companies can leverage growth opportunities and strengthen their market presence in dynamic and evolving markets.

Challenges:

Despite the favorable growth prospects, the acrylic polymer market faces several challenges that may impact its trajectory. One such challenge is the volatility of raw material prices and supply chain disruptions. Acrylic polymers rely on petrochemical-based feedstocks such as propylene and ethylene, making them susceptible to fluctuations in oil prices and geopolitical factors. Price volatility and supply chain uncertainties can affect manufacturing costs, profit margins, and pricing strategies, posing challenges for market players to maintain competitiveness and profitability.

Additionally, regulatory compliance and product stewardship represent challenges for acrylic polymer manufacturers, particularly concerning environmental regulations, safety standards, and product labeling requirements. Compliance with stringent regulations, such as REACH in Europe and TSCA in the United States, necessitates comprehensive risk assessments, toxicological evaluations, and regulatory submissions for acrylic polymer products. Ensuring regulatory compliance, product safety, and environmental sustainability requires significant resources, expertise, and ongoing monitoring to mitigate risks and maintain market access.

Moreover, competition from alternative materials and substitutes poses challenges for the acrylic polymer market. Growing demand for bio-based polymers, biodegradable materials, and alternative technologies such as nanomaterials and graphene-based coatings introduces competitive pressures and market disruptions. Manufacturers must innovate and differentiate their acrylic polymer offerings through performance enhancements, customization capabilities, and value-added services to retain market share and address evolving customer preferences.

Read Also: Bispecific Antibodies Market Size, Trends, Report by 2033

Recent Developments

- On February 9, 2023, Roehm, a chemical company based in Germany, unveiled two acrylic-based copolymer compounds, Cyrolite GP-20 and MD zk6, during the 2023 MD&M West trade show. Designed for injection molding and extrusion processes, these compounds demonstrated an outstanding combination of properties ideal for medical device applications.

Acrylic Polymer Market Companies

- BASF SE

- Dow Chemical Company

- Arkema SA

- Mitsubishi Chemical Corporation

- Evonik Industries AG

- Sumitomo Chemical Co., Ltd.

- LG Chem Ltd.

- Solvay SA

- Formosa Plastics Corporation

- Kuraray Co., Ltd.

- Nippon Shokubai Co., Ltd.

- DIC Corporation

- Celanese Corporation

- Mitsui Chemicals, Inc.

- Saudi Basic Industries Corporation (SABIC)

Segments Covered in the Report

By Type

- Polymethyl Methacrylate

- Sodium Polyacrylate

- Polyvinyl Acetate

- Polyacrylamide

- Others

By Solution Type

- Water-Borne

- Solvent-Borne

By Application

- Dentistry

- Cosmetics

- Paints & Coatings

- Cleaning

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/