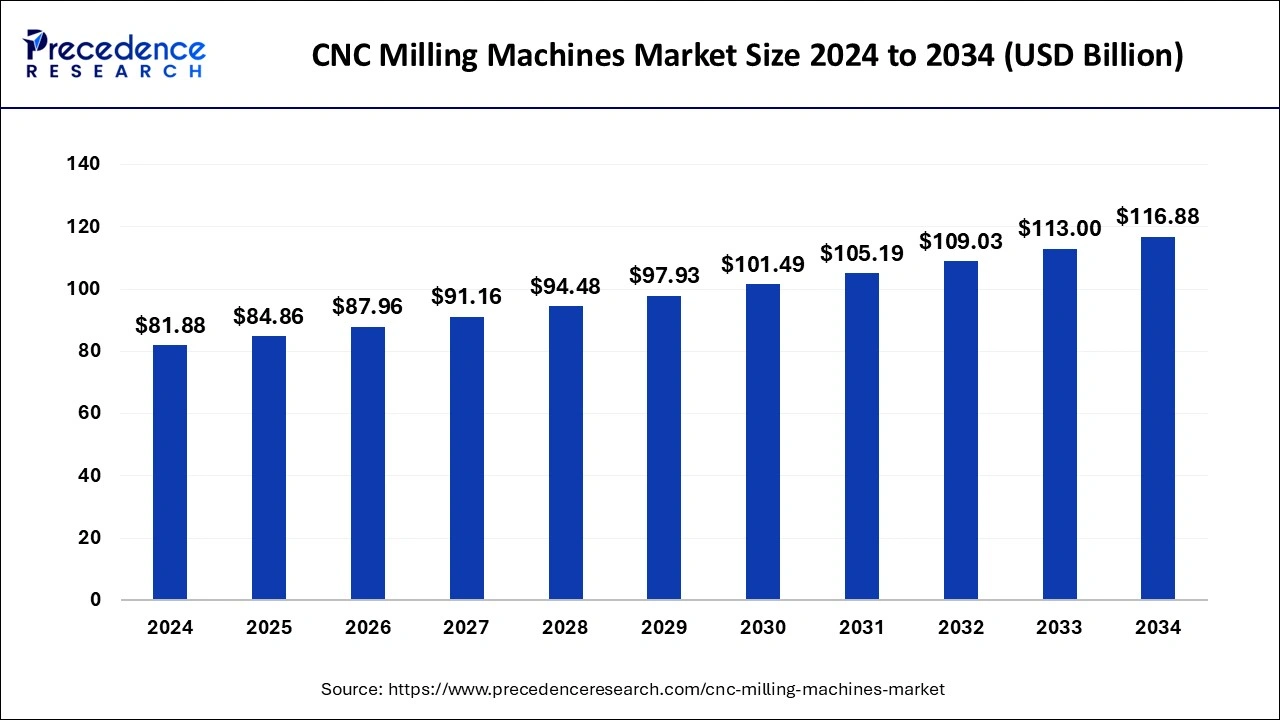

The global CNC milling machines market size was estimated at USD 79 billion in 2023 and is projected to rise to around USD 113 billion by 2033, growing at a CAGR of 3.64% from 2024 to 2033.

Key Points

- Asia-Pacific held a dominant share in the CNC milling machines market in 2023 with 43%.

- Europe will be the fastest growing region during the forecast period.

- According to product type, the vertical CNC milling machines segment dominated the market.

- The universal CNC milling machines segment will show a significant growth rate during the forecast period.

- According to axis type, the 3-axis segment dominated the market and contributed to the largest market share during the forecast period.

- According to end user type, the automotive segment dominated the market and accounted for most of the market share.

- The aerospace and defence segment will have a significant share of market in the forecast period.

The CNC (Computer Numerical Control) milling machines market is a rapidly growing segment within the manufacturing and engineering industries. CNC milling machines are automated, computer-controlled devices that perform precision milling and cutting operations on materials such as metal, plastic, and wood. These machines are known for their efficiency, accuracy, and ability to produce complex parts with high precision. CNC milling machines are widely used in various industries, including automotive, aerospace, medical devices, electronics, and more. The market for CNC milling machines is expected to grow significantly in the coming years due to the increasing demand for high-quality, precise parts in these industries.

Growth Factors:

- Technological Advancements: The integration of advanced technologies such as AI, IoT, and automation in CNC milling machines is enhancing their capabilities and efficiency. These technologies allow for real-time monitoring, predictive maintenance, and improved machine performance.

- Increasing Demand for Precision Components: Industries such as aerospace, automotive, and medical devices require high-precision components for their products. CNC milling machines offer the necessary precision and repeatability to meet these demands.

- Rising Adoption in Emerging Markets: Emerging economies such as India, China, and Brazil are experiencing rapid industrialization and urbanization. This has led to an increased demand for CNC milling machines in these regions.

- Growing Need for Automation: Manufacturers are increasingly turning to automation to improve productivity, reduce labor costs, and enhance product quality. CNC milling machines provide an efficient and cost-effective solution for these needs.

- Customization and Flexibility: CNC milling machines offer the ability to customize and produce complex parts with ease. This flexibility is driving demand from industries that require unique and intricate components.

Region Insights:

- North America: North America is one of the largest markets for CNC milling machines due to its well-established manufacturing sector, particularly in the automotive and aerospace industries. The region’s focus on innovation and technological advancements contributes to the growth of the market.

- Europe: Europe is another major market for CNC milling machines, with strong demand from the automotive, aerospace, and healthcare industries. Countries such as Germany and the UK have a robust manufacturing base that drives the market.

- Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth in the CNC milling machines market. Rapid industrialization, growing investments in infrastructure, and a large manufacturing base in countries such as China and India are key factors contributing to this growth.

- Latin America: Latin America is an emerging market for CNC milling machines, with increasing investments in manufacturing and infrastructure projects. Brazil and Mexico are key markets in the region.

- Middle East & Africa: The Middle East and Africa region is experiencing growing interest in CNC milling machines due to investments in manufacturing and construction projects. The region’s strategic location and access to global markets contribute to its potential for growth.

CNC Milling Machines Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 3.64% |

| Global Market Size in 2023 | USD 79 Billion |

| Global Market Size in 2024 | USD 81.88 Billion |

| Global Market Size by 2033 | USD 113 Billion |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Product Type, By Axis Type, and By End-User |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

CNC Milling Machines Market Dynamics

Drivers:

- Precision and Efficiency: CNC milling machines offer high precision and efficiency in producing complex parts, making them a preferred choice for industries that require accuracy.

- Cost-Effective Production: Automation and the ability to produce parts in large quantities reduce production costs, making CNC milling machines a cost-effective option for manufacturers.

- Versatility: CNC milling machines can work with a variety of materials and perform a range of operations, making them versatile and suitable for different industries.

- Skilled Workforce Availability: As CNC milling technology becomes more prevalent, there is a growing pool of skilled workers who can operate these machines, further driving market growth.

- Government Support: Governments in various regions are supporting the adoption of advanced manufacturing technologies, including CNC milling machines, through incentives and policies.

Challenges:

- High Initial Investment: The cost of CNC milling machines can be prohibitive for some manufacturers, especially small and medium-sized enterprises (SMEs).

- Maintenance and Upkeep: CNC milling machines require regular maintenance and upkeep to ensure optimal performance, which can add to operational costs.

- Skilled Labor Shortage: While there is a growing pool of skilled workers, there is still a shortage of highly trained personnel who can operate and maintain CNC milling machines.

- Technological Complexity: The integration of advanced technologies such as AI and IoT can add complexity to CNC milling machines, requiring manufacturers to invest in training and support.

- Supply Chain Disruptions: Global supply chain disruptions, such as those caused by the COVID-19 pandemic, can impact the availability of CNC milling machines and their components.

Opportunities:

- Industry 4.0 Integration: The integration of CNC milling machines with Industry 4.0 technologies such as AI, IoT, and cloud computing offers opportunities for improved productivity and efficiency.

- Expansion into New Markets: As emerging economies continue to industrialize, there is potential for CNC milling machines to expand into new markets and industries.

- Customization and Niche Markets: The ability of CNC milling machines to produce customized and niche products offers opportunities for manufacturers to differentiate themselves and cater to specific market needs.

- Sustainable Manufacturing: CNC milling machines can contribute to sustainable manufacturing practices by reducing material waste and energy consumption, providing opportunities for environmentally conscious manufacturers.

- Collaborations and Partnerships: Collaborations between CNC milling machine manufacturers and other technology providers can lead to the development of innovative solutions and new market opportunities.

Read Also: Biopsy Needle Market Size to Rake USD 2.60 Billion by 2033

Recent Developments

- In February 2023, Shilpin Machine Tools Pvt. Ltd, which is a key player in the CNC machine tool manufacturing, organized its 13th exhibition, DIE AND MOULD INDIA 2024. The event was scheduled from 14th February to 17th february, at Bombay Exhibition Center in Goregaon, Mumbai. In this exhibition, the founder and director of Shilpin Machine Tools, Abhay Deshmukh, addressed the challenges that are faced regarding polishing and machining. The event also saw the launch of highly precise machine Acuka.

- In August 2023, CGTech, a leading CNC machine simulation software, announced the launch of their latest version of VERICUT, VERICUT 9.4. It will offer some excellent fatures compared to the old version. CGTech has provided solutions in a wide range of domains, incluuding aerospace, oil and gas, and medical technology. The new version of VERICUT enables the best use of resources. The software has a ToolsUnited interface, which gives access to 40 tool manufacturers, and an improved tool data.

CNC Milling Machines Market Companies

- Doosan

- F-Zimmermann

- DMG MORI SEIKI

- HYUNDAI WIA

- Gleason Corporation

- GF Machining Solutions Management

- Haas Automation

- The CHIRON Group

- GROB-WERKE

Segments covered in the Reports

By Product Type

- Vertical CNC Milling Machines

- Horizontal CNC Milling Machines

- Universal CNC Milling Machines

By Axis Type

- 3-Axis

- 4-Axis

- Others

By End-User

- Automotive

- Electrical and Electronics

- Aerospace and Defense

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/