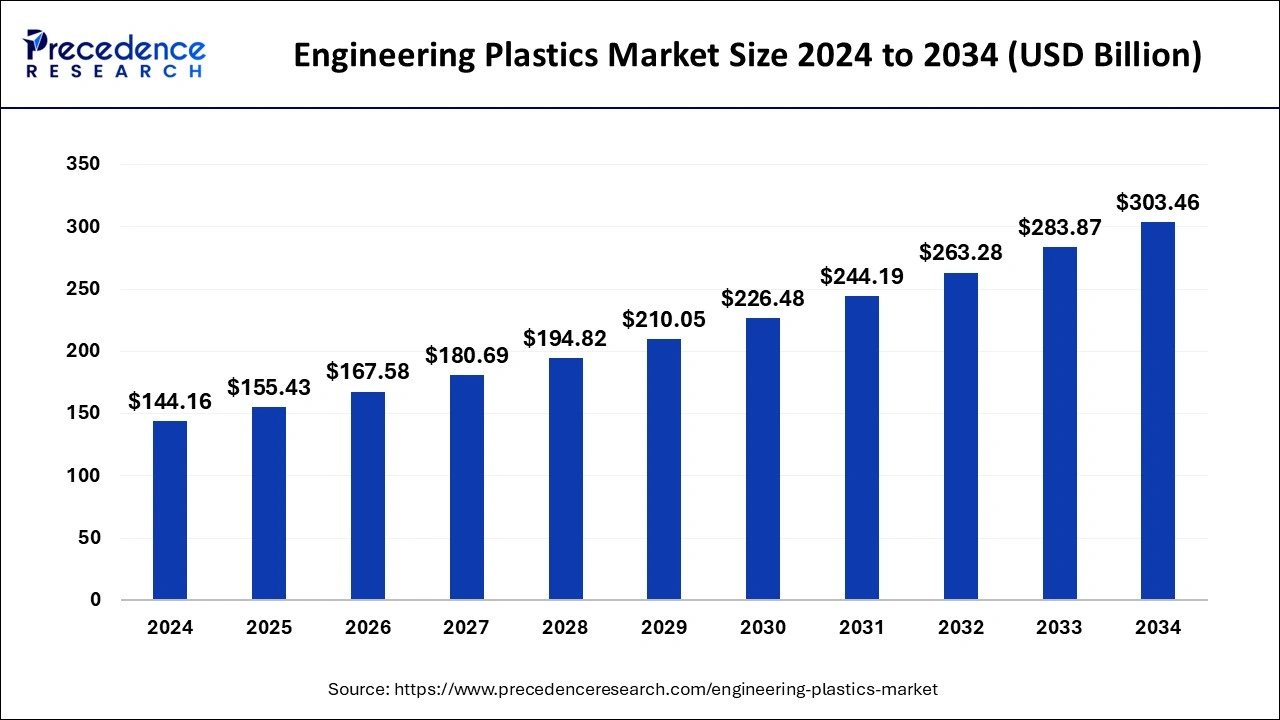

The global engineering plastics market size was calculated at USD 133.70 billion in 2023 and is predicted to rise around USD 283.87 billion by 2033, growing at a CAGR of 7.82% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market with the highest market share of 45% in 2023.

- North America held a notable share of the market in 2023.

- By resin type, the styrene copolymers (ABS and SAN) segment has held the largest market share of 35% in 2023.

- By resin type, the polycarbonate (PC) is expected to grow at a notable CAGR during forecast period.

- By end-use, the automotive & transportation segment accounted for the major market share of 365 in 2023.

- By end-use, the electrical & electronics segment is expected to grow to the highest CAGR during forecast period.

The engineering plastics market is a dynamic sector within the broader plastics industry, characterized by the production and utilization of high-performance polymers designed for demanding applications in various industries. Engineering plastics exhibit superior mechanical properties, heat resistance, chemical resistance, and dimensional stability compared to commodity plastics, making them ideal for use in automotive, electrical and electronics, consumer goods, and aerospace sectors. This market encompasses a diverse range of materials such as polyamide (nylon), polycarbonate, polyacetal, polyphenylene sulfide (PPS), and polyetheretherketone (PEEK), each tailored to meet specific performance requirements.

Get a Sample: https://www.precedenceresearch.com/sample/4256

Growth Factors

Several factors contribute to the growth of the engineering plastics market. One key driver is the increasing demand for lightweight materials in automotive manufacturing to improve fuel efficiency and reduce emissions. Engineering plastics offer a viable alternative to metal components, enabling weight reduction without compromising on performance or safety. Additionally, advancements in polymer science and manufacturing technologies have led to the development of new formulations with enhanced properties, expanding the application potential of engineering plastics across industries. Moreover, the growing trend towards miniaturization and durability in electronic devices fuels demand for engineering plastics with excellent electrical and thermal properties.

Region Insights

The engineering plastics market exhibits regional variations influenced by factors such as industrialization, infrastructure development, and regulatory landscape. Developed regions like North America and Europe have well-established engineering plastics industries driven by automotive and electronics sectors. Asia Pacific, led by countries such as China, Japan, and South Korea, dominates global production and consumption due to rapid industrial growth, robust manufacturing infrastructure, and strong demand from end-user industries. Emerging markets in Latin America and the Middle East are also witnessing steady growth as industrialization progresses and investments in infrastructure increase.

Engineering Plastics Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 7.82% |

| Global Market Size in 2023 | USD 133.70 Billion |

| Global Market Size in 2024 | USD 144.16 Billion |

| Global Market Size by 2033 | USD 283.87 Billion |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Resin Type and By End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Engineering Plastics Market Dynamics

Drivers

Several drivers underpin the growth of the engineering plastics market. The versatility and performance characteristics of engineering plastics make them attractive for replacing traditional materials like metals and ceramics in various applications, leading to increased adoption across industries. Furthermore, stringent regulations aimed at reducing vehicle weight and enhancing energy efficiency propel the use of engineering plastics in automotive manufacturing. The expanding electronics industry, driven by innovations in consumer electronics and telecommunications, creates substantial demand for engineering plastics with excellent electrical insulation and thermal management properties.

Opportunities

The engineering plastics market offers promising opportunities for innovation and collaboration across the value chain. Research and development efforts focus on developing bio-based and recyclable engineering plastics to address environmental concerns and meet sustainability goals. The adoption of additive manufacturing (3D printing) technologies enables the production of complex components using engineering plastics, opening up new design possibilities and customization options. Moreover, partnerships between material suppliers, manufacturers, and end-users facilitate the development of application-specific solutions tailored to industry requirements.

Challenges

Despite its growth trajectory, the engineering plastics market faces certain challenges. One significant challenge is the volatility of raw material prices, particularly in the case of specialty polymers, which can impact production costs and profitability. Another challenge lies in addressing concerns related to plastic waste and recycling, as engineering plastics are often used in durable applications that require effective end-of-life management. Additionally, stringent performance and regulatory requirements necessitate continuous investment in research and development to develop advanced formulations that meet evolving industry standards.

Read Also: Invisible Orthodontics Market Size to Rise USD 75.92 Bn by 2033

Engineering Plastics Market Recent Developments

- In April 2024, Nylon Corporation of America (NYCOA), a custom manufacturer of engineered nylon resins, announced the launch of NY-Clear, an amorphous 6I/6T nylon that is targeted for packaging and precision molded applications.

- In October 2023, Polyplastics launched Sarpek polyether ketone (PEK), an advanced material for metal replacement and applications requiring the highest heat resistance of any injection moldable resin without post-curing. Sarpek PEK is an engineering plastic in the upper end of the crystalline super engineering plastic hierarchy, an advancement upon polyetheretherketone (PEEK) that delivers a high crystallization rate and superior molding efficiency.

- In May 2023, Borealis launched Stelora, a new class of sustainable engineering polymer offering increased strength, durability, and a step change in heat-resistance capability. Stelora, which developed in collaboration with TOPAS Advanced Polymers, the world’s leading producer of cyclic olefin copolymer (COC). It is created using a unique process that combines COCs, which are a relatively new class of clear, high-purity polymer, with polypropylene (PP).

Engineering Plastics Market Companies

- Grand Pacific Petrochemical Corporation

- Mitsubishi Engineering-Plastics Corporation

- Wittenburg Group

- Piper Plastics Corp.

- Chevron Phillips Chemical Company LLC

- Daicel Corporation

- Evonik Industries AG

- Nylon Corporation of America (NYCOA)

- Eastman Chemical Company

- Ascend Performance Materials

- Ravago

- Teknor Apex

- Trinseo LLC

- Polyplastics Co., Ltd.

- Ngai Hong Kong Company Ltd.

- Ginar Technology Co., Ltd.

Segment Covered in the Report

By Resin Type

- Styrene Copolymers (ABS and SAN)

- Fluoropolymer

- Ethylene Tetrafluoroethylene (ETFE)

- Fluorinated Ethylene-propylene (FEP)

- Polytetrafluoroethylene (PTFE)

- Polyvinyl Fluoride (PVF)

- Polyvinylidene Fluoride (PVDF)

- Liquid crystal polymer (LCP)

- Polyamide (PA)

- Aramid

- Polyamide (PA) 6

- Polyamide (PA) 66

- Polyphthalamide

- Polybutylene Terephthalate (PBT)

- Polycarbonate (PC)

- Polyether Ether Ketone (PEEK)

- Polyethylene Terephthalate (PET)

- Polyimide (PI)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

By End-use

- Automotive & Transportation

- Electrical & Electronics

- Building & Construction

- Consumer Goods & Appliances

- Industrial

- Aerospace

- Medical

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/