Table of Contents

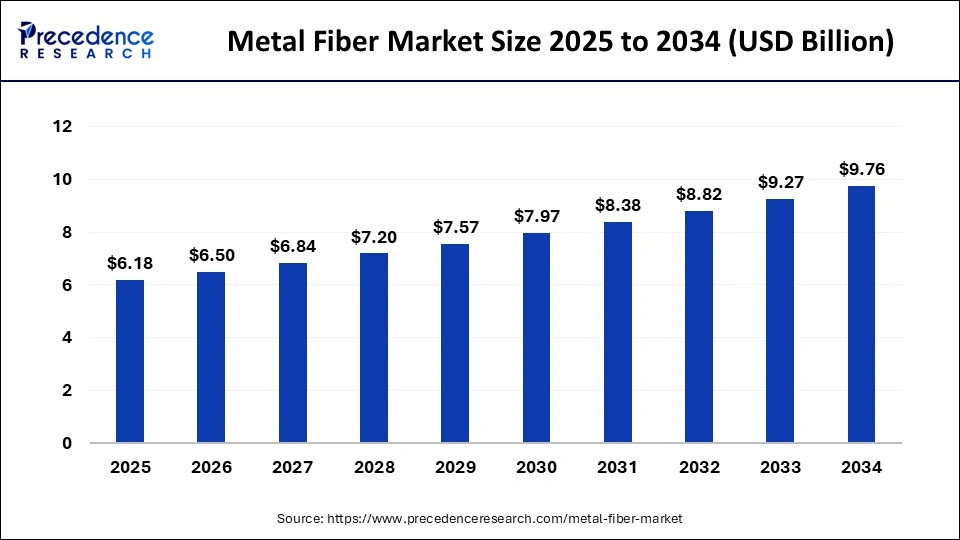

The global metal fiber market size is expected to reach around USD 9.76 billion by 2034 from USD 5.88 billion in 2024, at a CAGR of 5.2%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1151

Metal fibers are fine strands or filaments made from metals such as steel, aluminum, copper, and their alloys. These fibers are produced by various methods, including extrusion, drawing, and electrospinning, to form fibers with specific diameters ranging from micrometers to millimeters. Metal fibers are unique due to their excellent properties such as high conductivity, strength, durability, heat resistance, and corrosion resistance. These fibers find applications in a wide range of industries, including automotive, aerospace, electronics, textiles, and construction.

Factors Driving Market Growth

Several factors contribute to the growth of the global metal fiber market, making it an attractive industry for investment and innovation. These include:

1. Rising Demand for Lightweight and High-Strength Materials

The demand for lightweight and high-strength materials is one of the primary drivers of the metal fiber market. In industries such as aerospace and automotive, there is a growing need for materials that can provide strength without adding excessive weight. Metal fibers are increasingly used to create composite materials that meet these requirements, as they offer a combination of strength, lightness, and flexibility. The growing adoption of electric vehicles (EVs) and the need for lighter components to improve fuel efficiency and battery range also contribute to the demand for metal fibers.

2. Advancements in Manufacturing Technologies

Technological advancements in the production of metal fibers have made it easier and more cost-effective to manufacture these materials in various forms and specifications. The development of new and improved techniques such as advanced extrusion and drawing technologies has enhanced the properties of metal fibers, making them suitable for an expanding range of applications. Additionally, the rise of 3D printing and additive manufacturing is enabling the production of customized metal fiber components with high precision and complex geometries, further driving the market’s growth.

3. Growing Demand in the Electronics and Electrical Industries

Metal fibers are widely used in the electronics industry due to their high electrical conductivity. They are used in components such as cables, connectors, and heat exchangers. With the increasing reliance on electronic devices, the demand for metal fibers in the electronics and electrical sectors is expected to grow significantly. The rise of the Internet of Things (IoT), 5G technology, and smart devices are expected to further contribute to the demand for metal fibers, as these technologies rely heavily on advanced materials with superior conductivity and performance.

4. Environmental Sustainability and Recycling Initiatives

Environmental concerns and the need for sustainable manufacturing processes have led to an increased focus on recycling and reducing the environmental impact of industrial production. Metal fibers are highly recyclable, making them an attractive option for manufacturers looking to reduce their carbon footprint. The ability to recycle metal fibers without significant degradation in performance or quality makes them a viable option for sustainable manufacturing, particularly in industries like automotive and construction, where sustainability is becoming a key concern.

5. Growing Demand in the Textile Industry

The textile industry is another significant contributor to the growth of the metal fiber market. Metal fibers are increasingly used in the production of protective clothing, industrial fabrics, and functional textiles. For example, metal fibers are used in the production of fire-resistant and heat-resistant clothing for workers in industries such as oil and gas, construction, and firefighting. As the demand for specialized textiles and protective garments rises, the use of metal fibers in the textile industry is expected to expand.

Also Read: https://www.dailytechbulletin.com/chemiluminescence-immunoassay-market/

Applications of Metal Fibers

Metal fibers are used across a wide range of industries due to their versatile properties. Some of the key applications of metal fibers include:

1. Automotive Industry

In the automotive sector, metal fibers are used in the production of lightweight composite materials for vehicle components. These materials offer enhanced strength-to-weight ratios, which are essential for improving fuel efficiency and performance. Metal fibers are also used in filters, exhaust systems, and catalytic converters due to their high thermal and chemical resistance.

2. Aerospace Industry

The aerospace industry is another major consumer of metal fibers. They are used in aircraft components such as structural parts, heat shields, and insulating materials. Metal fibers help reduce weight while ensuring the structural integrity and durability of aircraft components, which is crucial for ensuring safety and performance in flight.

3. Electronics and Electrical Components

As mentioned earlier, metal fibers are widely used in the electronics and electrical industries due to their excellent electrical conductivity. They are used in cables, circuit boards, and connectors. Their ability to conduct electricity efficiently while being lightweight makes them ideal for modern electronics, which require high performance and reliability.

4. Textiles and Protective Clothing

The use of metal fibers in textiles is growing due to their unique properties, including conductivity, heat resistance, and durability. They are used in protective clothing such as fire-resistant suits, industrial gloves, and high-performance sportswear. Additionally, metal fibers are used in the production of electromagnetic shielding textiles, which are essential for protecting sensitive electronic equipment from electromagnetic interference (EMI).

5. Construction Industry

In the construction industry, metal fibers are used in reinforced concrete and other composite materials. These fibers enhance the strength and durability of concrete, making them ideal for applications in infrastructure such as bridges, tunnels, and high-rise buildings. The ability to reduce the risk of cracking and improve the longevity of construction materials is a key advantage of using metal fibers in the construction industry.

Regional Insights

The global metal fiber market is influenced by regional factors such as industrial development, technological advancements, and the regulatory environment. Some of the key regions driving the market include:

North America

North America, particularly the United States, is a significant market for metal fibers. The region’s strong industrial base, particularly in aerospace, automotive, and electronics, contributes to the high demand for metal fibers. Additionally, the growing emphasis on sustainability and environmental regulations is driving the adoption of recyclable metal fibers in manufacturing.

Europe

Europe is another key market for metal fibers, with countries like Germany, France, and the United Kingdom leading the way in industrial applications. The region has a well-established automotive and aerospace industry, both of which are major consumers of metal fibers. The increasing demand for electric vehicles and sustainable manufacturing practices further boosts the market growth in this region.

Asia Pacific

The Asia Pacific region is expected to experience the highest growth rate in the metal fiber market over the forecast period. The rapid industrialization of countries such as China, India, and Japan, coupled with the growing demand for advanced materials in automotive, electronics, and construction, is driving the market. The rise of manufacturing hubs and the increasing adoption of high-tech industries are also contributing to the demand for metal fibers in the region.

Middle East and Africa

The Middle East and Africa (MEA) region is seeing increasing demand for metal fibers in industries such as oil and gas, construction, and textiles. The region’s growing infrastructure projects and the demand for high-performance materials in extreme environments are expected to drive the market in this region.

Key Players in the Metal Fiber Market

Several global players dominate the metal fiber market. These companies are involved in the production, development, and supply of metal fibers to various industries. Some of the key players in the market include:

- IntraMicron, Inc.

- V. Bekaert S.A.

- PPG Industries Ohio Inc.

- Fiberguide Industries Limited

- Fibrometals SRL

- Green Steel Group

- MBC Metal Limited

- Nippon Seisen Co., Ltd

- Stanford Advanced Materials

- Addas Group

- Guven Metal

- BinNova Metal Fiber Technology GmbH

These companies are continuously investing in research and development to create advanced metal fibers with superior properties, such as improved conductivity, strength, and corrosion resistance.