Table of Contents

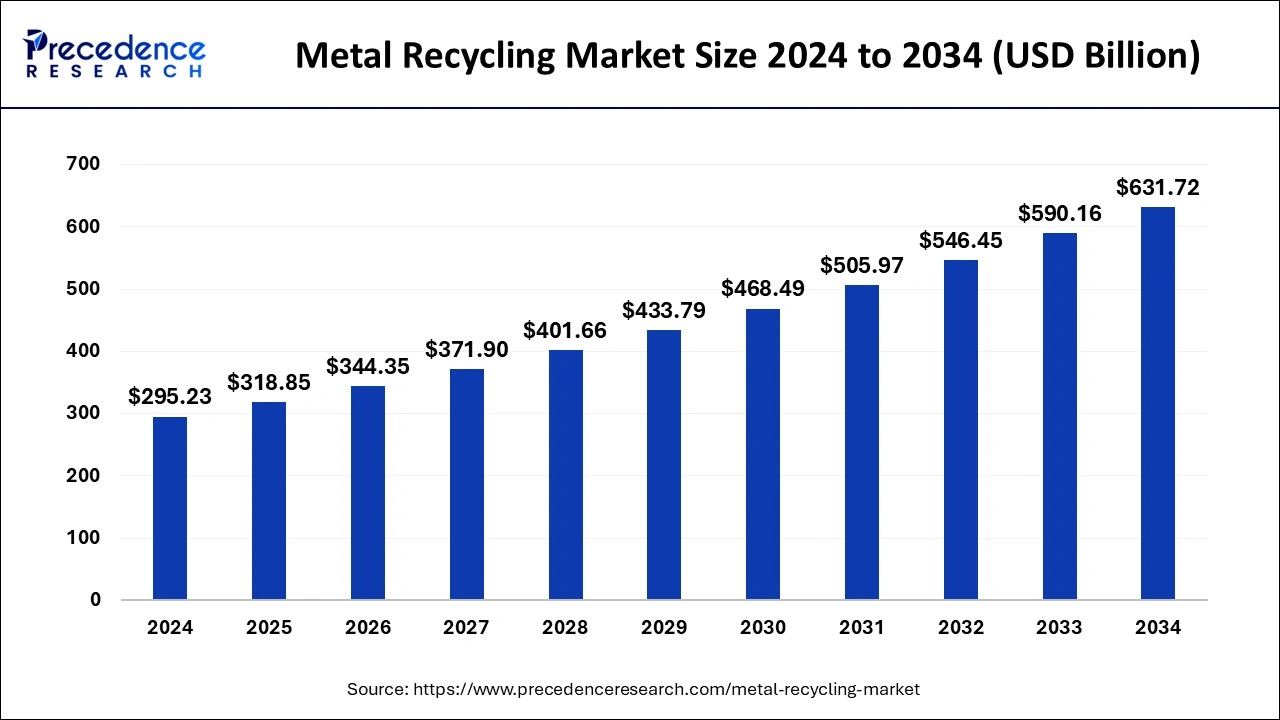

The global metal recycling market size is calculated at USD 295.23 billion in 2024 and is projected to reach around USD 631.72 billion by 2034 with a CAGR of 7.90%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1159

Key Points

- In 2024, steel led the metal recycling market as the dominant product segment.

- The construction sector emerged as the top application segment in the global metal recycling market in 2024.

- Asia Pacific accounted for the largest share of the global metal recycling market, contributing 51% of total revenue.

Understanding the Metal Recycling Market

Metal recycling refers to the process of recovering scrap metal from various sources, such as industrial waste, consumer goods, and discarded metal products, and reprocessing it into usable raw materials. Metals such as aluminum, steel, copper, lead, and zinc are commonly recycled due to their widespread use in industries like automotive, construction, electronics, and packaging.

Recycling metals offers numerous benefits, including:

- Conservation of Resources: Recycling helps conserve finite natural resources, reducing the need for mining and extraction, which are resource-intensive and harmful to the environment.

- Energy Efficiency: Recycling metal requires less energy than producing new metal from raw materials. For example, recycling aluminum saves up to 95% of the energy compared to primary production.

- Reduction of Greenhouse Gas Emissions: By reducing energy consumption, recycling metal also helps lower greenhouse gas emissions, contributing to climate change mitigation efforts.

- Economic Opportunities: The metal recycling industry creates job opportunities and stimulates economic growth by turning waste into valuable raw materials.

As the global population grows and industrial activities increase, the demand for metals and the need for efficient recycling practices will continue to rise.

AI Revolutionizing Metal Recycling

1. Enhanced Sorting and Processing Efficiency

- AI-powered automated sorting systems improve the accuracy and speed of metal separation, reducing contamination.

- Machine learning algorithms optimize recycling processes by identifying valuable metals with greater precision.

- AI-driven robotics streamline dismantling and shredding operations, increasing overall efficiency and reducing labor costs.

2. Cost Reduction and Sustainability

- AI minimizes waste in the recycling process by improving material recovery rates, reducing landfill disposal.

- Predictive analytics help recycling companies optimize resource allocation, cutting down operational expenses.

- AI-powered monitoring systems enhance equipment maintenance, preventing downtime and reducing repair costs.

3. Market Expansion and Innovation

- AI fosters the development of smart recycling facilities with real-time tracking and data-driven decision-making.

- The integration of AI attracts investments in advanced recycling technologies, expanding market opportunities.

- AI-driven insights help companies meet regulatory compliance and sustainability goals, enhancing market growth.

Read Also: Medical Imaging Outsourcing Market

The Rising Importance of Metal Recycling in a Sustainable Future

Market Overview

Metal recycling has gained significant attention as industries seek sustainable solutions to reduce waste and conserve natural resources. The market has grown steadily due to the increased use of recycled metals in various industries, such as construction, automotive, and packaging. Advanced recycling technologies have enhanced efficiency, making metal recovery more viable and cost-effective. With the global push toward sustainability, the demand for recycled metals is expected to continue rising.

Market Drivers

Key drivers of the metal recycling market include increasing industrialization and urbanization, which lead to higher metal consumption and waste generation. Government regulations aimed at reducing environmental pollution and promoting sustainable manufacturing practices are also playing a crucial role in market expansion. Additionally, the rising adoption of electric vehicles (EVs) and renewable energy solutions is driving the need for recycled metals such as aluminum, copper, and lithium.

Opportunities

Significant opportunities exist in developing advanced recycling technologies, including AI-based sorting systems and robotic automation, to improve efficiency and reduce contamination in metal recycling. The rising trend of extended producer responsibility (EPR) policies is encouraging manufacturers to invest in recycling infrastructure. Additionally, growing investments in smart cities and green construction projects are increasing the demand for high-quality recycled metals.

Challenges

One of the major challenges in the metal recycling industry is the high initial investment required for setting up advanced processing facilities. Inconsistent scrap metal quality due to contamination and improper sorting also affects market growth. Additionally, fluctuating global metal prices create uncertainty in the recycling business, making it difficult for companies to maintain stable profit margins.

Regional Insights

Asia-Pacific dominates the global metal recycling market, with China and India being key contributors due to their extensive industrial activities and growing sustainability initiatives. North America is also a major player, with strong regulations supporting metal recycling efforts. Europe continues to drive innovation in recycling technology and sustainable practices, while Latin America and Africa are gradually expanding their recycling capabilities through infrastructure development and government support.

Metal Recycling Market Companies

- GFG Alliance

- European Metal Recycling

- CMC Recycling

- Kimmel Scrap Iron & Metal Co. Inc.

- Norsk Hydro ASA

- Schnitzer Steel Industries, Inc.

- Tata Steel

- Novelis

- Utah Metal Works

- Sims Metal Management Limited

Latest Announcement by Industry Leaders

- Roland Harings, CEO of Aurubis AG, commented that the U.S. market has huge potential for strategic growth and the company aims to become a fully integrated copper producer that uses recycling materials in North America as well. He also said that the company will invest $1.3 million globally in eight projects by the end of the 2025-2026 fiscal year.

Recent Developments

- In November 2024, Nupur Recyclers Ltd. announced its expansion into the recycling of metal scraps and lithium-ion batteries. The expansion was made due to the growing demand for sustainable and eco-friendly industrial solutions.

- In September 2024, researchers from Rice University developed a novel method of recycling valuable metals from electronic waste using the flash Joule Heating method. The new process reduces the environmental impact and increases efficiency, decreasing cost.

Segments Covered in the Report

By Product

- Aluminum

- Steel

- Copper

- Others

By Application

- Automotive

- Construction

- Industrial Goods

- Consumer Goods

- Others

By Regional

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/