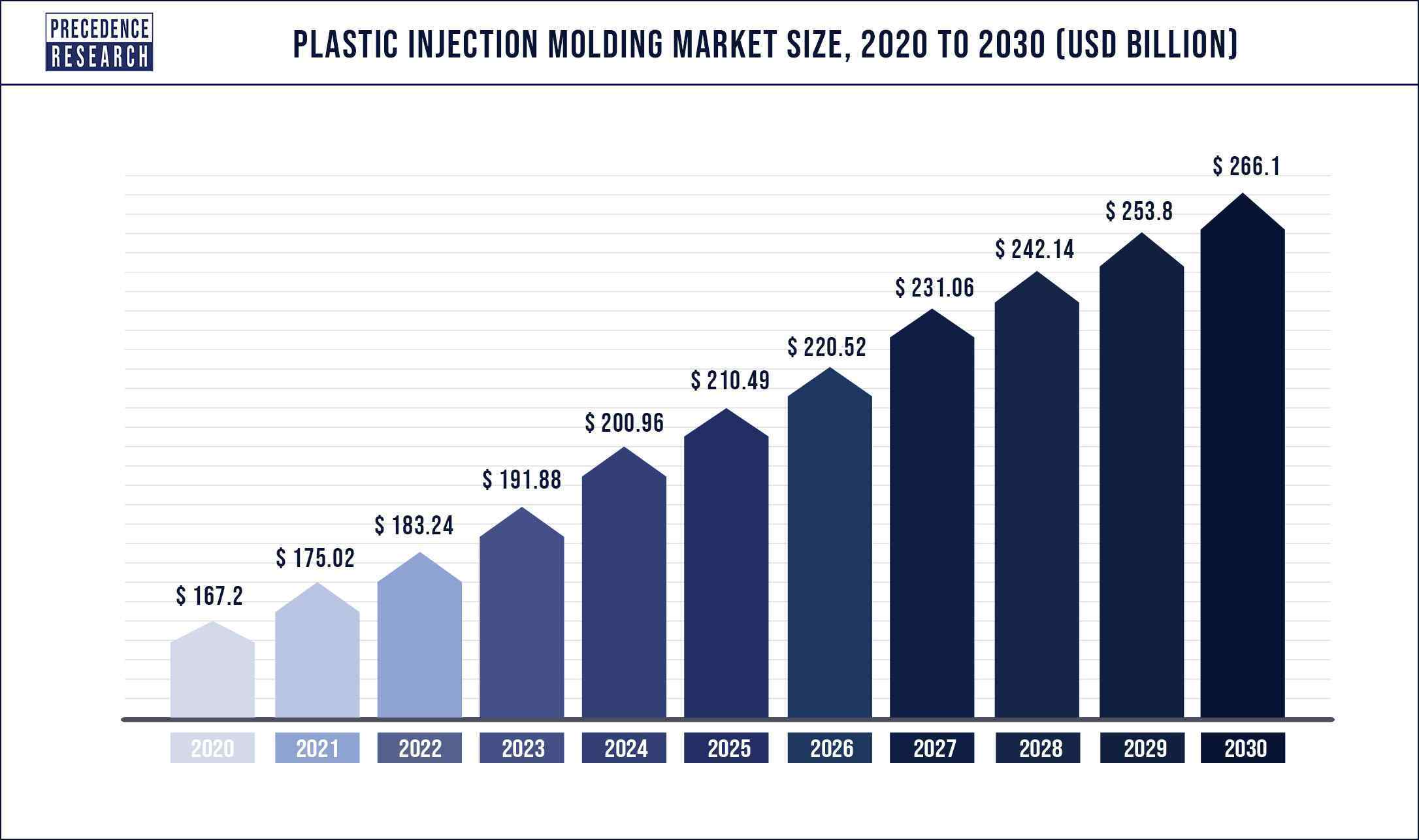

The plastic injection molding market size is predicted to reach USD 266.1 billion by 2030 and is expected to register a CAGR of 4.8% from 2022 to 2030.

The study provides an analysis of the period 2017-2030, wherein 2022 to 2030 is the forecast period and 2021 is considered as the base year.

The market revenue/volume with the help of widespread quantitative and qualitative insights, and forecasts of the market. This report presents a breakdown of the market into forthcoming and niche segments. Additionally, this research study gauges market revenue growth and its drift in global, regional, and country from 2017 to 2030.

Download a Free Sample Copy of this Report@ https://www.precedenceresearch.com/sample/1488

The plastic injection molding market is expected to be driven by rising demand for plastic components from various end use sectors such as packaging, automotive, household appliances, medical devices, and electrical and electronics. The injection molded technology has grown in importance in the mass manufacturing of difficult plastic shapes as a result of modern advancements to reduce the rate of defective production.

The molded plastics have a wide range of uses in a variety of industries. The biggest demand generators are the automobile, electronics, and construction industries. As a result of the rise of these industries, plastic injection molding market’s share is steadily expanding.

Table of Contents

Scope of the Plastic Injection Molding Market

| Report Coverage | Details |

| Market Size in 2020 | USD 167.2 Billion |

| Growth Rate from 2021 to 2030 | 4.8% |

| Revenue Projection by 2030 | USD 266.1 Billion |

| Largest Market | Asia Pacific |

| Fastest Growing Market | Europe |

| Base Year | 2021 |

| Forecast Period | 2021 to 2030 |

Market Dynamics

Drivers

Surge in demand for plastic injection molding in diverse sectors

The plastic injection molding market is expanding due to rising demand for molded plastics in various end-user industries. The injection molding process enables the mass production of plastic goods with high efficiency and minimal resource waste. As a result, its market share is growing as a result of its low production costs and high reproducibility. Injection molded plastic has a wide range of applications in a variety of end-user industries.

The automotive industry is also increasing its demand for lightweight and long-lasting objects to replace heavy metal parts. Similarly, the expansion of the packaging, construction, and pharmaceutical industries is increasing demand for injection molded plastics. Furthermore, technological advancements in molding technology will undoubtedly benefit the injection molding industry and fuel plastic injection molding market growth.

Restraints

High cost of manufacturing technology

The high initial cost of injection molding machines is the primary growth constraint in the global plastic injection molding market. As petroleum products are raw materials for the plastic industry, the fluctuating nature of fuel prices limits market growth. Furthermore, growing concern about the negative environmental impact of plastics, as well as research into alternatives, will have a negative impact on the market.

Opportunities

Increased emphasis on light weight materials to reduce fuel consumption

Injection molded plastics are used to make a variety of automotive parts, including wheel covers, enclosures, consoles, headlight housings, and interior parts. Their high tensile strength, chemical corrosion resistance, lightweight, durability, and high resistance to physical impact have encouraged manufacturers to replace metal parts in automotive design. The implementation of stringent vehicle emission regulations, as well as a greater emphasis on fuel efficiency, has increased demand for lightweight vehicles, propelling the plastic injection molding market in these regions.

Furthermore, automotive manufacturers are effectively utilizing injection molded plastics because they provide improved recyclability, durability, abrasion resistance, vibration control, and strength. Injection molded plastics also allow manufacturers to reduce production costs, facilitate modular assembly, and improve vehicle exterior aerodynamics. Thus, increased emphasis on light weight materials to reduce fuel consumption is creating lucrative opportunities for the growth of plastic injection molding market during the forecast period.

Challenges

Presence of alternative technologies

There are several other cost-effective methods that limit the use of injection molding. The plastic injection molding is a high-cost technology that limits the market growth even more. The emerging technologies like 3-dimensional (3D) printing are evolving all the time and can now create miniature things that are similar to injection molded ones. In the near future, further improvement in such technologies is projected to have a detrimental influence on demand for plastic injection molding products.

Read Also: Oncology Market Value to Hit US$ 581.25 Bn by 2030 – Daily Tech Bulletin

Report Highlights

- Polypropylene is the most popular form of injection molded plastic in the world. This dominance is due to polypropylene’s superior physical and chemical characteristics. It’s less expensive than other plastics and has a high flexural strength. It is water resistant and offers resistance to a wide range of chemical reactions.

- By application, the packaging segment dominates the plastic injection molding market. Packaging plastics are in high demand in the pharmaceutical, food and beverage, and consumer packaged goods industries.

Regional Snapshot

Asia-Pacific is the largest segment for plastic injection molding market in terms of region. In developing countries of the Asia-Pacific region, rising infrastructure spending combined with rising automotive demand is expected to drive the market penetration. Due to the low labor costs in the Asia-Pacific nations such as Japan, China, and South Korea and major end use industries like automobile and electronics are driving the market growth.

Europe region is the fastest growing region in the plastic injection molding market. The cosmetics, pharmaceuticals, and home chemicals are some of the packaging applications in the Europe region. The consumables and electronics applications demand is predicted to be driven by rising demand for electronic appliances like laptops and cell phones, notably in the developed regions.

Some of the prominent players in the global plastic injection molding market include:

- Magna International Inc.

- Toshiba Corporation

- DOW Inc.

- LyondellBasell

- HTI Plastics

- DuPont

- Valder Kunststoffverarbeitungs GmbH

- Huntsman Corporation

- Coastal Plastic Molding Inc.

- BASF SE

Segments Covered in the Report

By Raw Material

- Polypropylene

- AcrylonitrileButadieneStyrene

- Polystyrene

- High Density Polyethylene

- Others

By Application

- Automobile

- Consumer Goods

- Electronics

- Packaging

- Building & Construction

- Healthcare

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

Key Points Covered in plastic injection molding market Study:

- Growth of plastic injection molding in 2022

- Market Estimates and Forecasts (2017-2030)

- Market Share Analysis

- Key Drivers and Restraints Shaping Market Growth

- Segment-wise, Country-wise, and Region-wise Analysis

- Competition Mapping and Benchmarking

- Recommendation on Key Winning Strategies

- COVID-19 Impact on Demand for plastic injection molding and How to Navigate

- Key Product Innovations and Regulatory Climate

- Consumption Analysis

- Production Analysis

- Market and Management

TABLE OF CONTENT

Chapter 1. Introduction

1.1. Research Objective

1.2. Scope of the Study

1.3. Definition

Chapter 2. Research Methodology

2.1. Research Approach

2.2. Data Sources

2.3. Assumptions & Limitations

Chapter 3. Executive Summary

3.1. Market Snapshot

Chapter 4. Market Variables and Scope

4.1. Introduction

4.2. Market Classification and Scope

4.3. Industry Value Chain Analysis

4.3.1. Raw Material Procurement Analysis

4.3.2. Sales and Distribution Channel Analysis

4.3.3. Downstream Buyer Analysis

Chapter 5. COVID 19 Impact on Plastic Injection Molding Market

5.1. COVID-19 Landscape: Plastic Injection Molding Industry Impact

5.2. COVID 19 – Impact Assessment for the Industry

5.3. COVID 19 Impact: Global Major Government Policy

5.4. Market Trends and Opportunities in the COVID-19 Landscape

Chapter 6. Market Dynamics Analysis and Trends

6.1. Market Dynamics

6.1.1. Market Drivers

6.1.2. Market Restraints

6.1.3. Market Opportunities

6.2. Porter’s Five Forces Analysis

6.2.1. Bargaining power of suppliers

6.2.2. Bargaining power of buyers

6.2.3. Threat of substitute

6.2.4. Threat of new entrants

6.2.5. Degree of competition

Chapter 7. Competitive Landscape

7.1.1. Company Market Share/Positioning Analysis

7.1.2. Key Strategies Adopted by Players

7.1.3. Vendor Landscape

7.1.3.1. List of Suppliers

7.1.3.2. List of Buyers

Chapter 8. Global Plastic Injection Molding Market, By Raw Material

8.1. Plastic Injection Molding Market, by Raw Material Type, 2021-2030

8.1.1. Polypropylene

8.1.1.1. Market Revenue and Forecast (2019-2030)

8.1.2. AcrylonitrileButadieneStyrene

8.1.2.1. Market Revenue and Forecast (2019-2030)

8.1.3. Polystyrene

8.1.3.1. Market Revenue and Forecast (2019-2030)

8.1.4. High Density Polyethylene

8.1.4.1. Market Revenue and Forecast (2019-2030)

8.1.5. Others

8.1.5.1. Market Revenue and Forecast (2019-2030)

Chapter 9. Global Plastic Injection Molding Market, By Application

9.1. Plastic Injection Molding Market, by Application, 2021-2030

9.1.1. Automobile

9.1.1.1. Market Revenue and Forecast (2019-2030)

9.1.2. Consumer Goods

9.1.2.1. Market Revenue and Forecast (2019-2030)

9.1.3. Packaging

9.1.3.1. Market Revenue and Forecast (2019-2030)

9.1.4. Electronics

9.1.4.1. Market Revenue and Forecast (2019-2030)

9.1.5. Building & Construction

9.1.5.1. Market Revenue and Forecast (2019-2030)

9.1.6. Healthcare

9.1.6.1. Market Revenue and Forecast (2019-2030)

Chapter 10. Global Plastic Injection Molding Market, Regional Estimates and Trend Forecast

10.1. North America

10.1.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.1.2. Market Revenue and Forecast, by Application (2019-2030)

10.1.3. U.S.

10.1.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.1.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.1.4. Rest of North America

10.1.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.1.4.2. Market Revenue and Forecast, by Application (2019-2030)

10.2. Europe

10.2.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.2.2. Market Revenue and Forecast, by Application (2019-2030)

10.2.3. UK

10.2.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.2.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.2.4. Germany

10.2.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.2.4.2. Market Revenue and Forecast, by Application (2019-2030)

10.2.5. France

10.2.5.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.2.5.2. Market Revenue and Forecast, by Application (2019-2030)

10.2.6. Rest of Europe

10.2.6.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.2.6.2. Market Revenue and Forecast, by Application (2019-2030)

10.3. APAC

10.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.3.3. India

10.3.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.3.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.3.4. China

10.3.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.3.4.2. Market Revenue and Forecast, by Application (2019-2030)

10.3.5. Japan

10.3.5.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.3.5.2. Market Revenue and Forecast, by Application (2019-2030)

10.3.6. Rest of APAC

10.3.6.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.3.6.2. Market Revenue and Forecast, by Application (2019-2030)

10.4. MEA

10.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.4.2. Market Revenue and Forecast, by Application (2019-2030)

10.4.3. GCC

10.4.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.4.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.4.4. North Africa

10.4.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.4.4.2. Market Revenue and Forecast, by Application (2019-2030)

10.4.5. South Africa

10.4.5.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.4.5.2. Market Revenue and Forecast, by Application (2019-2030)

10.4.6. Rest of MEA

10.4.6.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.4.6.2. Market Revenue and Forecast, by Application (2019-2030)

10.5. Latin America

10.5.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.5.2. Market Revenue and Forecast, by Application (2019-2030)

10.5.3. Brazil

10.5.3.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.5.3.2. Market Revenue and Forecast, by Application (2019-2030)

10.5.4. Rest of LATAM

10.5.4.1. Market Revenue and Forecast, by Raw Material (2019-2030)

10.5.4.2. Market Revenue and Forecast, by Application (2019-2030)

Chapter 11. Company Profiles

11.1. Magna International Inc.

11.1.1. Company Overview

11.1.2. Product Offerings

11.1.3. Financial Performance

11.1.4. Recent Initiatives

11.2. Toshiba Corporation

11.2.1. Company Overview

11.2.2. Product Offerings

11.2.3. Financial Performance

11.2.4. Recent Initiatives

11.3. DOW Inc.

11.3.1. Company Overview

11.3.2. Product Offerings

11.3.3. Financial Performance

11.3.4. Recent Initiatives

11.4. LyondellBasell

11.4.1. Company Overview

11.4.2. Product Offerings

11.4.3. Financial Performance

11.4.4. Recent Initiatives

11.5. HTI Plastics

11.5.1. Company Overview

11.5.2. Product Offerings

11.5.3. Financial Performance

11.5.4. Recent Initiatives

11.6. DuPont

11.6.1. Company Overview

11.6.2. Product Offerings

11.6.3. Financial Performance

11.6.4. Recent Initiatives

11.7. Valder Kunststoffverarbeitungs GmbH

11.7.1. Company Overview

11.7.2. Product Offerings

11.7.3. Financial Performance

11.7.4. Recent Initiatives

11.8. Huntsman Corporation

11.8.1. Company Overview

11.8.2. Product Offerings

11.8.3. Financial Performance

11.8.4. Recent Initiatives

11.9. Coastal Plastic Molding Inc.

11.9.1. Company Overview

11.9.2. Product Offerings

11.9.3. Financial Performance

11.9.4. Recent Initiatives

11.10. BASF SE

11.10.1. Company Overview

11.10.2. Product Offerings

11.10.3. Financial Performance

11.10.4. Recent Initiatives

Chapter 12. Research Methodology

12.1. Primary Research

12.2. Secondary Research

12.3. Assumptions

Chapter 13. Appendix

13.1. About Us

13.2. Glossary of Terms

Thanks for reading you can also get individual chapter-wise sections or region-wise report versions such as North America, Europe, or the Asia Pacific.

Buy Full Research Report (Single User License US$ 4500) @ https://www.precedenceresearch.com/checkout/1488

Contact Us:

Precedence Research

Apt 1408 1785 Riverside Drive Ottawa, ON, K1G 3T7, Canada

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Website: https://www.precedenceresearch.com