Polypropylene Market

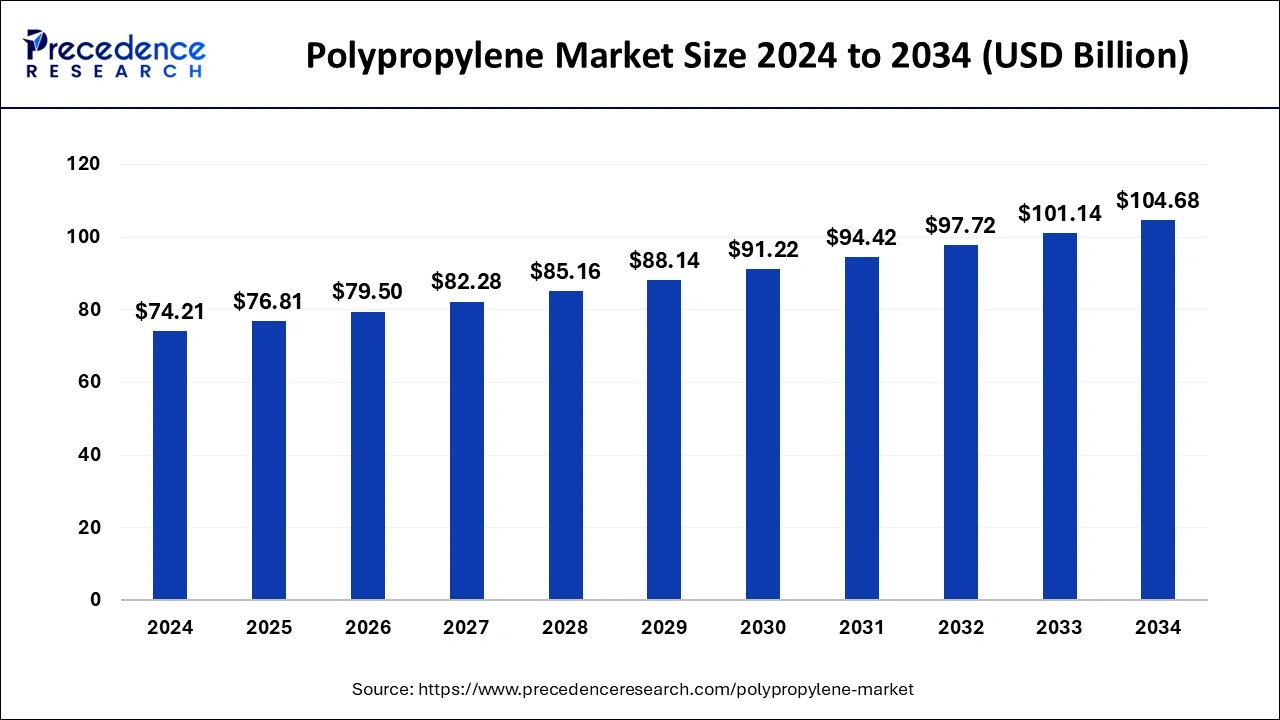

The global polypropylene market size valued at USD 74.21 billion in 2024 and is expected to Surpass around USD 104.68 billion by 2034, with a CAGR of 5.40%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1153

Introduction to Polypropylene

Polypropylene is a polymer made from the polymerization of propylene monomers. It is a thermoplastic polymer, meaning it can be molded and reshaped when heated, making it highly adaptable for various uses. Polypropylene stands out due to its exceptional properties, including high chemical resistance, mechanical strength, and a high melting point, which make it an ideal choice for applications requiring durability and versatility. Additionally, polypropylene is lightweight, relatively inexpensive to produce, and has a low environmental footprint, which is increasingly important as industries look for more sustainable alternatives to other plastics.

Polypropylene’s ability to be molded into a variety of shapes and sizes has made it a popular choice in multiple industries, ranging from packaging to automotive manufacturing. It is available in several forms, such as homopolymers, copolymers, and impact copolymers, each offering specific properties suitable for different applications.

Key Drivers of Market Growth

Several factors are driving the expansion of the global polypropylene market, including increasing industrial applications, technological advancements, and the rising demand for sustainable materials.

1. Growing Demand in Packaging Industry

The packaging industry is one of the largest consumers of polypropylene, accounting for a significant portion of the global demand. Polypropylene’s excellent chemical resistance, flexibility, and ability to withstand varying temperatures make it ideal for producing packaging materials such as containers, bottles, films, and food packaging. As global e-commerce and retail industries continue to expand, the demand for polypropylene-based packaging materials is set to grow significantly.

Additionally, the increasing consumer preference for lightweight, durable, and sustainable packaging materials has further contributed to polypropylene’s widespread use. As manufacturers shift toward recyclable and eco-friendly packaging solutions, polypropylene’s recyclability and lower carbon footprint are driving its adoption in the packaging sector.

2. Increasing Automotive Industry Demand

The automotive industry is another major driver of the polypropylene market. Polypropylene is widely used in vehicle interiors, bumpers, dashboards, and various other components due to its durability, lightweight nature, and cost-effectiveness. As car manufacturers look to reduce vehicle weight to improve fuel efficiency and meet stringent environmental regulations, polypropylene is being increasingly used in the production of automobile parts.

The demand for electric vehicles (EVs) is also contributing to the growth of the polypropylene market. The lightweight nature of polypropylene is critical in EVs, where every gram of weight reduction directly impacts the range and energy efficiency of the vehicle. Polypropylene’s strength-to-weight ratio makes it ideal for use in automotive components such as battery cases, electrical connectors, and interior trim.

3. Rise of Sustainable Solutions

The global push for sustainability has significantly influenced the demand for polypropylene. Polypropylene is a recyclable material, and efforts to improve recycling technologies are increasing its appeal as a sustainable plastic. The ability to reuse polypropylene for manufacturing new products helps reduce waste and the environmental impact of plastic production. With the increasing global emphasis on circular economies and sustainability, industries are looking for more eco-friendly alternatives to traditional plastics, further boosting polypropylene’s popularity.

Additionally, polypropylene-based products, such as biodegradable packaging and eco-friendly textiles, are gaining traction in consumer markets due to their reduced environmental impact compared to other materials. The growing trend of using sustainable and renewable materials has contributed to the steady rise in polypropylene consumption across various sectors.

4. Technological Advancements in Polypropylene Production

Advances in polypropylene production techniques, such as the development of high-performance catalysts and more efficient polymerization processes, have led to better-quality polypropylene products with improved properties. These advancements have expanded the range of applications for polypropylene, enabling the production of products with enhanced durability, strength, and resistance to temperature and chemicals.

New production methods also contribute to cost savings, making polypropylene more affordable compared to other thermoplastics. As a result, industries seeking cost-effective solutions are increasingly turning to polypropylene for both primary and secondary manufacturing processes.

Also Read: https://www.dailytechbulletin.com/industrial-lubricants-market-size/

Applications of Polypropylene Across Industries

Polypropylene’s versatility allows it to be used across a wide range of industries. Below are some of the primary sectors driving demand for polypropylene:

1. Packaging Industry

Polypropylene is widely used in packaging, especially for food and beverage products. It is used in the manufacturing of containers, bottles, films, and trays, as it offers excellent barrier properties, is resistant to moisture, and can be easily molded into various shapes. Polypropylene is also used for creating transparent packaging that offers clarity and strength, ensuring that products are protected and remain visually appealing to consumers.

In addition to food packaging, polypropylene is used in non-food applications, such as packaging for consumer goods, industrial products, and personal care items. The rise in demand for flexible packaging solutions is also pushing the need for polypropylene materials that offer both durability and flexibility.

2. Automotive Industry

Polypropylene is widely used in the automotive sector for various components such as bumpers, dashboards, and interior parts. Its lightweight properties help reduce the overall weight of vehicles, which is crucial for improving fuel efficiency. The material’s durability and ability to withstand high temperatures also make it an ideal choice for many automotive applications.

Polypropylene is also used for exterior components like wheel covers and trims, where its resistance to impact and environmental stress is highly beneficial. With the growing trend of using sustainable materials in the automotive sector, polypropylene-based components are becoming increasingly popular due to their recyclability.

3. Textile Industry

The textile industry is another significant consumer of polypropylene, particularly for producing nonwoven fabrics. Nonwoven fabrics made from polypropylene are widely used in a range of applications, including diapers, medical supplies, filters, and hygiene products. The lightweight nature and resistance to chemicals and moisture make polypropylene an ideal material for such applications.

Polypropylene fibers are also used in carpets, upholstery, and clothing due to their ability to withstand wear and tear while maintaining their strength and appearance. The demand for polypropylene fibers is expected to rise, especially in emerging markets where consumer demand for affordable and durable textiles is increasing.

4. Healthcare and Medical Applications

Polypropylene is used extensively in healthcare applications, including medical packaging, surgical instruments, and medical devices. Its biocompatibility and resistance to chemicals and heat make it ideal for producing products that come into direct contact with patients. Polypropylene is used in the production of medical syringes, bottles, vials, and even sutures, ensuring hygiene and safety for medical professionals and patients.

The demand for polypropylene in medical and healthcare applications is expected to grow as the global healthcare sector continues to expand, particularly in developing countries with increasing healthcare needs.

5. Construction and Agriculture

Polypropylene is used in construction applications, particularly for manufacturing pipes, insulation, and geotextiles. Its durability, resistance to moisture, and ability to withstand harsh conditions make it an ideal material for both indoor and outdoor construction products. Polypropylene is also used in agricultural applications, such as in greenhouse films, irrigation systems, and crop protection, where its resistance to UV light and chemicals is essential.

Regional Insights

North America

North America is one of the leading regions in the polypropylene market, driven by strong demand from industries such as automotive, packaging, and healthcare. The United States, being one of the largest producers and consumers of polypropylene, is expected to continue leading the market in the region. Additionally, the growing focus on sustainable materials and environmentally friendly solutions is boosting polypropylene consumption across various sectors.

Europe

Europe is another key market for polypropylene, particularly in countries like Germany, France, and the United Kingdom. The demand for polypropylene in the automotive, packaging, and healthcare industries continues to grow, driven by advancements in production technology and the increasing shift towards sustainability. The European Union’s regulatory framework, which encourages the use of recyclable and eco-friendly materials, has further contributed to the adoption of polypropylene.

Asia-Pacific

Asia-Pacific is expected to witness the highest growth rate in the polypropylene market due to the rapid industrialization of countries like China, India, and Southeast Asian nations. The region’s growing automotive, packaging, and textile industries, coupled with increasing demand for polypropylene in emerging markets, are driving market growth. Additionally, the growing adoption of polypropylene-based packaging solutions in consumer goods is further fueling the demand.

Latin America and Middle East & Africa

The Latin American and Middle East & Africa regions are expected to see steady growth in polypropylene consumption, with increasing demand from industries like packaging, automotive, and construction. As the manufacturing base in these regions continues to expand, the demand for polypropylene is expected to rise steadily.

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/