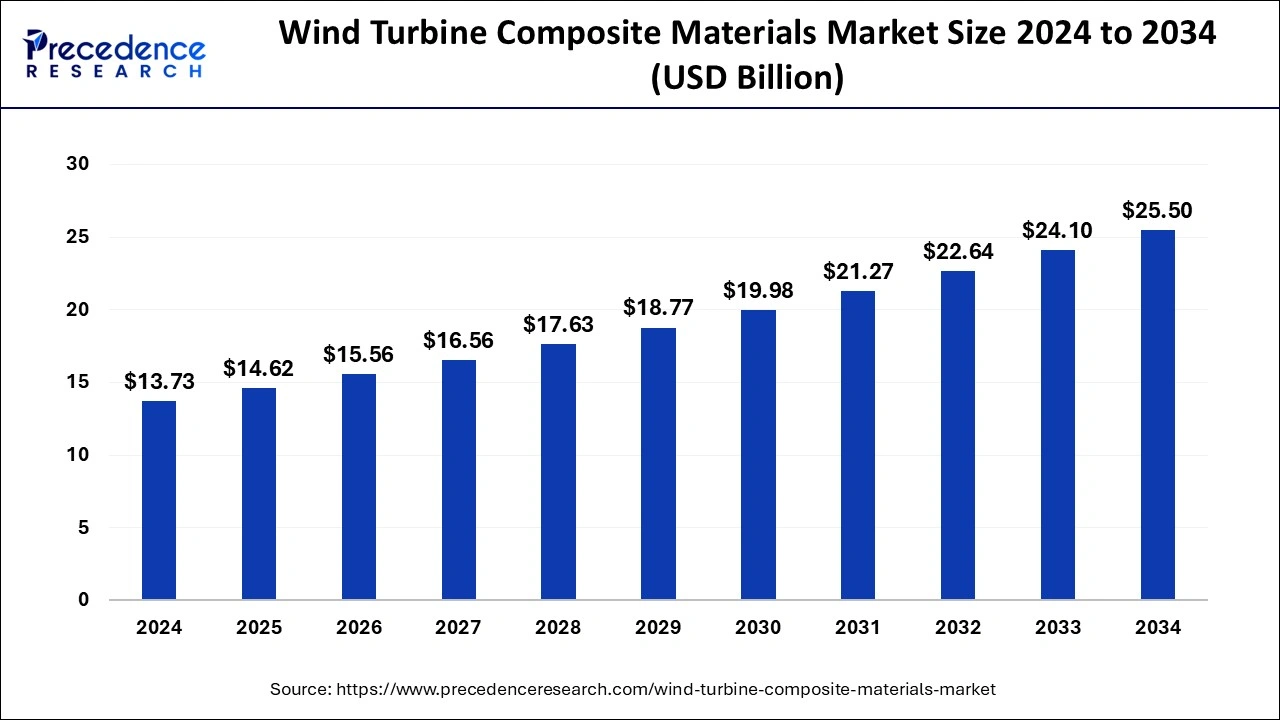

The global wind turbine composite materials market size was estimated at USD 12.90 billion in 2023 and is projected to attain around USD 24.10 billion by 2033, growing at a CAGR of 6.44% from 2024 to 2033.

Key Points

- Asia Pacific dominated the market in 2023 with the largest share 35%.

- North America is anticipated to grow at a notable growth rate in the wind turbine composite materials market during the forecast period.

- By fiber type, the glass fiber segment held the largest share of around 65% in 2023.

- By fiber type, the carbon fiber segment is expected to grow significantly during the forecast period.

- By technology, the vacuum injection molding segment accounted for the dominating share of 45% in 2023.

- By technology, the prepreg segment is observed to witness a considerable growth rate in the global wind turbine composite materials market over the forecast period.

- By application, the wind blades segment held the dominating share of 75% in 2023.

Wind turbine composite materials play a crucial role in the construction and operation of modern wind turbines, which are vital for renewable energy generation. These materials, typically composed of a combination of fibers (such as glass, carbon, or aramid) embedded in a resin matrix (usually epoxy or polyester), offer several advantages over traditional materials like steel or concrete.

One of the primary benefits of composite materials in wind turbines is their lightweight nature. Compared to steel, composites have a much higher strength-to-weight ratio, allowing for the design and construction of larger turbine blades that can capture more wind energy efficiently. This lightweight characteristic also reduces the overall mass of the turbine, which can lead to lower installation and transportation costs.

Get a Sample: https://www.precedenceresearch.com/sample/4067

Moreover, wind turbine composite materials offer superior fatigue resistance and durability, making them well-suited for the harsh operating conditions experienced by wind turbines. The flexible nature of composites allows turbine blades to bend and flex in response to changing wind loads, reducing stress concentrations and extending the lifespan of the turbine components. Additionally, composites are resistant to corrosion and degradation from environmental factors, ensuring long-term performance and reliability in offshore and coastal wind farm installations.

Wind Turbine Composite Materials Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 6.44% |

| Global Market Size in 2023 | USD 12.90 Billion |

| Global Market Size in 2024 | USD 13.73 Billion |

| Global Market Size by 2033 | USD 24.10 Billion |

| Largest Market | Asia-Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Fiber Type, By Technology, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Another advantage of composite materials is their design flexibility and versatility. Manufacturers can tailor the properties of composite materials through the selection of fiber types, resin formulations, and manufacturing techniques to meet specific performance requirements. This flexibility enables the optimization of turbine blade designs for maximum energy capture, aerodynamic efficiency, and structural integrity.

Furthermore, wind turbine composite materials contribute to the sustainability of wind energy systems. Composites are typically recyclable and can be reused or repurposed at the end of their lifecycle, reducing the environmental impact of turbine decommissioning and disposal. Additionally, the lightweight nature of composites reduces the overall material and energy consumption associated with wind turbine manufacturing and operation.

Despite these advantages, there are also challenges associated with the use of composite materials in wind turbines. One challenge is the cost of materials and manufacturing processes, which can be higher compared to traditional materials like steel. However, ongoing advancements in composite manufacturing technologies, process automation, and economies of scale are helping to reduce costs and improve the cost-effectiveness of wind turbine composites.

Another challenge is the maintenance and repair of composite turbine blades. While composites offer excellent durability and fatigue resistance, they can still be susceptible to damage from impacts, erosion, and fatigue over time. Effective inspection, monitoring, and repair strategies are essential to ensure the continued performance and reliability of composite turbine components throughout their operational lifespan.

Read Also: Data Center Transformation Market Size, Share, Report by 2033

Recent Developments

- According to a BSE filing, in June 2023, SJVN Green Energy, a subsidiary of SJVN Ltd, secured a 200 MW wind power project through a tariff-based competitive bidding process conducted by the Solar Energy Corporation of India. This project requires an investment of Rs 1,400 crore. SJVN Green Energy will undertake the development of this wind power project anywhere in India through an EPC (engineering procurement construction) contract.

- Amazon now has more than 500 wind and solar projects globally, and once operational, they are expected to generate more than 77,000 gigawatt-hours (GWh) of clean energy each year, or enough to power 7.2 million U.S. homes.

Wind Turbine Composite Materials Market Companies

- TPI Composites Inc.

- Huntsman International LLC

- Teijin Limited

- TPI Composites Inc.

- LM Wind Power

- Suzlon Energy Limited

- Gurmit Holding AG

- LM Wind Power

- Molded Fiber Glass Companies

- Toray Industries, Inc.

- Vestas Wind Systems A/S

- Siemens Gamesa Renewable Energy, S.A.U.

- Hexcel Corporation

- Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd

- Others

Segments Covered in the Report:

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Others

By Technology

- Vacuum Injection Molding

- Prepreg

- Hand Lay-Up

- Others

By Application

- Wind blades

- Nacelles

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/